This case study demonstrates how Power Towers increase safety when working at heights on the example of our customer – LeGrand.

LeGrand is a global specialist in electrical infrastructures. The company was founded in France, and throughout the years it was established in multiple countries and continents. In 2022, LeGrand increased its turnover by 20% and made 8 billion euros of profit.

Challenge

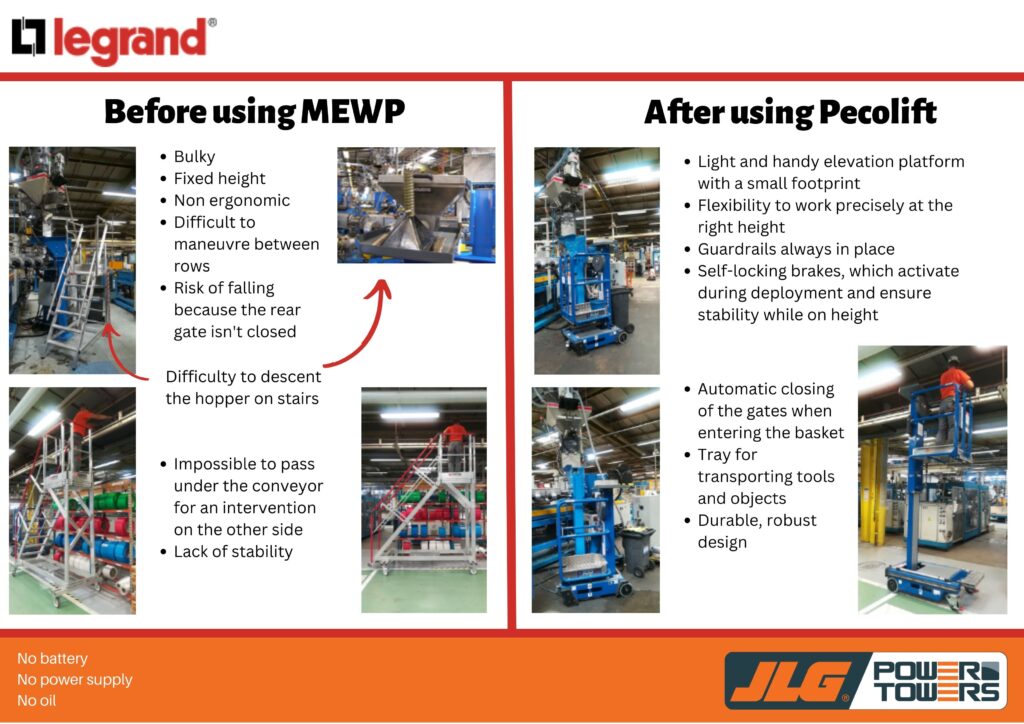

LeGrand came to Power Towers with multiple challenges to solve. Prior to Power Towers platforms the company used traditional ladders during their projects. The client reported difficulties maneuvering between rows and ascending/descending the ladder on the stairs. LeGrand was concerned about the ergonomics and safety of their workers. The ladders the company used were bulky, unstable, and risky to use because the rear gate wasn’t closed. In addition, the fixed height of the access equipment LeGrand used at that time complicated access to infrastructure on multiple levels. The last major concern was the inability to pass under the aerial conveyor and intervene on the other side.

Audit

To be able to offer the most suitable product to the client’s needs, the salesperson from Power Towers conducted a field audit. Some of the most significant outcomes were:

- The ES46 safety stepladder allows access to overhead conveyors while remaining along the central aisle.

- Access to the ICTA conveyor with this equipment is impossible regarding height and width.

- Ascents must be aided by voluntary braking; otherwise, the wheels are in motion during the ascending process and there is a risk of falling.

- The stepladder doors are not fitted with return springs, so they can remain open. This factor increases the risk of falling from a ladder during work.

- Access to the flame-retardant hopper is impossible due to the corrugator and coextrusion foot position. These stepladders do not make it possible to stabilize the hopper safely during dismantling.

Solution

As a solution to the previously described issues, Power Towers offered the Pecolift series of elevating platforms. This is the machine from the push-around manual family, a lightweight platform with a small footprint of 0.99 m x 0.70 m. The manual elevation with an easy rotation of the wheel makes the machine available to use 24/7 without intermediate recharges. Pecolift provides LeGrand with the flexibility they needed to work at the required heights and reach places they couldn’t before. Self-locking brakes, which activate during deployment, ensure platform stability. The automatically locking guardrails prevent operators from falling. These features were created specifically to increase safety when working at heights. After using Pecolift, LeGrand reported improved working conditions, increased productivity, and reduced fatigue among workers.

If you would like to know more about our range of elevated platforms, please see the following link: Access Platforms · Buy Work Platforms | Power Towers

In case you wish to get advice from our sales team you can always contact us at Contact Page – Power Towers or write an email to sales@powertowers.com

For more information and updates subscribe to our newsletter or LinkedIn page.